Discussing power distribution is a case study in the ability to scale and accommodate. If as an AC you’ve had to plug in a FIZ, microforce, multiple monitors, wireless transmitters, cine tapes, you’ll know how much of a wiring hell things can be before you even start routing power and signal cables. It’s a battle between the nature of the hand you’re dealt, and applying a heaping sense of obsessive compulsive disorder towards keeping things neat and tidy. Moreover it’s just about feeding power to every required widget on the camera. Sometimes these systems are nothing more than a power strip for your camera, and that’s okay. It does the job. But sometimes you get a lot more than that, in the case of OffHollywood’s offerings.

From the outset I’ll set the stage as stating I own a RED Epic Dragon, but when I AC I giggle uncontrollably when I get to work on the ARRI Alexa. And that stems from that camera having a well thought out power distribution system (integrated into the body no less) that works well for the majority of projects I’ve been involved in. Specifically the ARRI works well in that it brings power in through it’s DC port (for example via an Anton Bauer VLCX brick battery) while distributing power out via 2x 3-pin ports, and 1x 2-pin port. It also has a 5-pin TC (timecode) in, which we’ll discuss later on. In addition to that you can throw a V-mount or more commonly an AB mounted brick, which serves as a nice hot swap when you’re changing VCLXs throughout the day (on those days spent on a dolly).

So where does that leave us with the Epic? Well, for most people it means using either something like the Switronix Jetpack, or an AB P-Tap splitter. Both offer their own pros and cons. A splitter sucks. It does the job, but then you’re dealing with a clunky plastic power strip essentially, combined with annoying connectors. I know RED has stated from the outset it detests P-Taps, but the reality is if you rent gear, you’ll want to accommodate for both P-Tap and Lemo. Also there’s no fuse inside and if you blow one in your battery plate, that’s at least 10-15 minutes to remove it, swap it out (assuming you have a 2.5amp fuse lying around, which you should, because reasons), and then hope you don’t blow the fuse again. Or in the case of the switronix having the same issues with blowing a fuse, but then adding lemos without the ability to carry R/S commands. It’s also bulky and just…whatever.

Okay, so that out of the way, what does OH bring to the market? Simply put, it’s smart power distribution while also adding REDLINK controls, either integrated, or as it’s own module. And to talk about that integration without discussion of FoolControl would be a travesty. So lets work through this piece by piece; Hotbox, Hotlink, and FoolControl.

The HotBox measures roughly 75mm x 90mm x 25mm. So it’s not big at all, but it packs a punch, containing 4x P-Taps (if that’s your only option for cabling), 2x 2-Pin Lemos, 1x 4-Pin, and 1x 3-pin. In addition to that it has USB power output (charging your iPhone off your camera? stylishly practical), and 5-pin TC input. It has a 12v power input for supplying power to your accessories. This can be powered via a P-Tap to 2-pin Lemo connector (via a battery plate), or Lemo to 2-Pin cable of your choice. In the case of the RED Epic there’s a Y-cable that breaks out of the HotBox, carrying two signals, control and sync. Control taking care of all of the operations from RED Link or FoolControl, and sync passing all run/stop and timecode information.

Let’s stop and talk about timecode for a second. If you’ve had to jam, you know how painfully aggravating the RED sync bnc breakout cable is, either to install, or to leave hanging there in the case of connecting to a LockIt box. Because the HotBox is always passing sync and control data, you’re able to always have a standard 5-pin TC Lemo port at the ready. Much like how the ARRI Alexa works. But there’s an advantage to the HotBox over even the Alexa in this regard, because unlike the Alexa you don’t need to change over the RED’s internal TC to external to accept that signal. If your audio guy gives you a LockIt with a BNC-to-5 Pin cable you plug it in, and a second later you have TC. Nothing is required as far as changing settings. It’s slick, and your audio guys will love you, either if you have to stab in TC every now and then, or leave a LockIt on the camera consistently. It’s just seamless, and it’s one less thing to worry about, and that’s a good thing when you have multiple AKS hooked up to the camera.

The fact that the HotBox passes sync data, in addition to powering devices, becomes a critical advantage when running wireless follow focuses such as Preston Cinema Systems 1 or 3 channel setups. Prior to the hotbox you would be required to use a BNC cable, connected to the previously mentioned RED Sync cables. And THEN you’d hook up a P-Tap to Preston cable. Not the most elegant of solutions. Because the HotBox carries signal data (R/S) via it’s 3 or 4 pin power cables (indicated by the little icon of the Running Man) it means via one cable you can power the Preston and have R/S capability. The HotBox translates all signals via ARRI standard R/S, so keep that in mind if you’re using a system with the option of RED Epic specific start stop commands, as it should be set to ARRI to properly R/S. The net benefit is you have one less cable (or two in the case of the RED sync cable + your R/S Preston cable).

The HotBox has an quickly removable 2 amp fuse, in case you do manage to throw too much power hungry accessories at it. From experience I would be aware of your devices’ power draw, as some systems may consume more power than 2 amps during boot up. Mark (OffHollywood) and I discovered that the RED 3-Channel system (or Element Technica) pulls about 2.5 amps during it’s motor calibration. As such this means for my specific setup I’m using a 3 amp fuse to avoid blowing the system. But because the system has an internal fuse, and is quickly swappable, it means that you’re not going to face blowing the battery plate’s 2.5amp fuse. So you have one more layer of protection on set. I’ve timed myself and the whole swap takes about 30 seconds, depending on fat fingers or not. Fuses are about a dollar or less, have a few of them in your kit for peace of mind. Done.

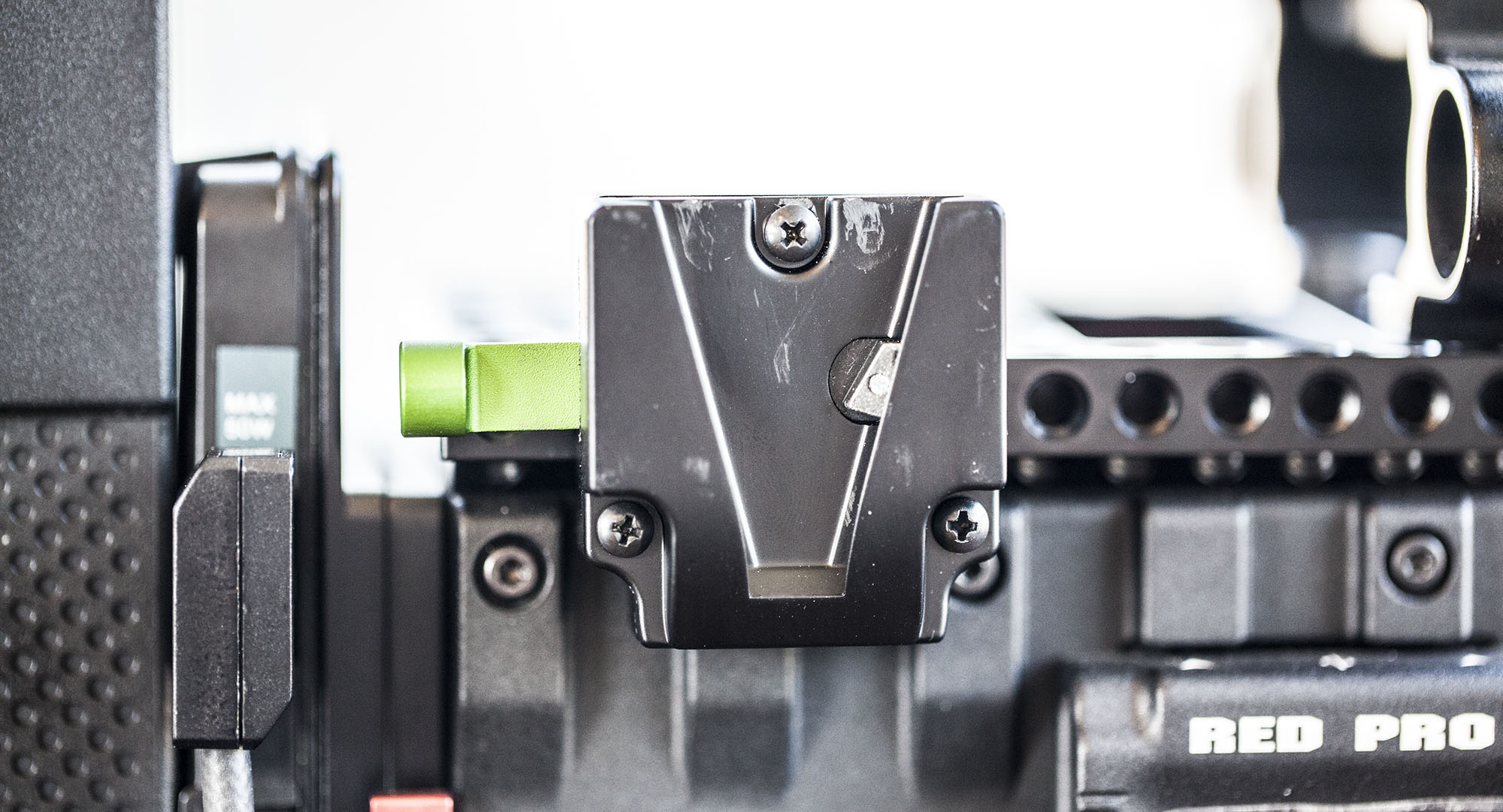

The system comes with a V-Mount male adapter, so it can be installed on 15/19mm clamps easily, or using something like a Element Technica V-Dock attached to a cheese plate. In addition there’s two pass-through holes on the bottom left and top right in case you want to use a set of long 1/4x20 screws. Really that’s about it in terms of layout. OffHollywood offers multiple power cables options for multiple devices (Mark’s cabling for the TVLogics is incredibly well made, and a huge step up above the OEM cables that are otherwise as thin as angel hair pasta). So really your only two challenges are figuring out where you want to mount the HotBox, and keeping a selection of cabling for your specific devices. However just having the hotbox, the power cable to drive it, and the RED DSMC cable to connect to a RED Epic is usually enough, with most rental houses providing Lemo cables for their systems already.

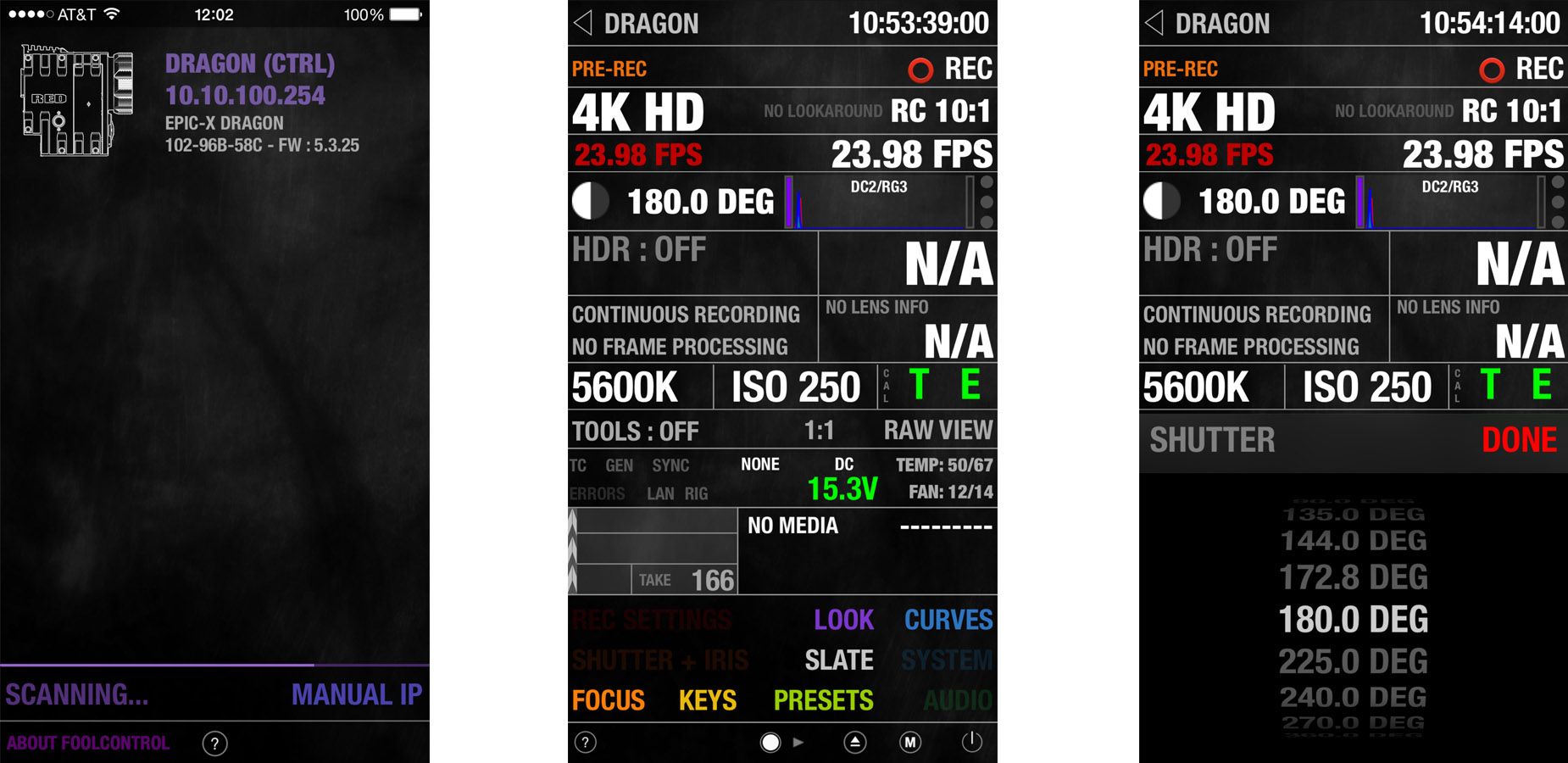

I think that covers it, except for the antenna. It’s got an antenna! But why? Well, great question. Either you’ve seen FoolControl, or you’ve used it. If you’ve used it, then high five, I don’t have to sell you on it already because you’ve already cleaned yourself up from that pool of your own saliva. The Hotbox smartly has a 802.11n module built in, thus serving as a RED Link protocol compatible adapter. That’s where the control cable part of that DSMC Y-cable comes into play. This passes input/output commands from the RED Epic brain to an iOS/OSX device using FoolControl.

The HotBox, and Hotlink (which I’ll discuss in the next paragraph), works on two different systems, as an access point, or ad hoc. What this means is that you can either directly connect to the HotBox/HotLink using a OSX or iOS device (either without a password, or you can secure the network connection), and get a range of about 100’ line of sight. But where it gets cooler is the ability to create an ad hoc network. Using a web portal (after connecting directly to the HotBox/Link) you can designate a pre-existing network for the device to automatically connect to, thus extending the range significantly. What this means, in real world terms, is that I can have a 802.11n router on my cart, or anywhere on set, that ONLY serves as a wireless network. The HotBox/Link connects to that network, and then my iOS device connects to that router. So what was once 100’ range via device to device, is now conceivably 4-5x that range. And if you’re using a system like the ASUS 87R/U routers that blast enough wifi to make you sterile from the microwaves, you can practically control the camera from craft services.

So the difference between the HotLink and the HotBox has to do with the intended capabilities of each system. The HotBox is a power distribution system and wireless controller. The HotLink is a wireless controller, and nothing more. As a result it’s half the mass of the HotBox, only having 3 ports; 2-pin power in, 4-pin control out, and USB micro power in (intended for situations like drones or gimbal work). The HotLink has a captive 1/4x20 screw for attaching to cheese plates. It’s wireless operation is exactly the same as the HotBox. I have both systems, as there are jobs where you either don’t have to power as many accessories, such as in light gimbal setups, or jib/crane work where you may not be using additional monitors/cine-tapes. The HotBox usually is equipped on the majority of my setups, especially when being utilized on studio shoots. How you decide which one you’ll need depends on how often you’ve banged your head against the prep table at a rental house trying to make 4-5 devices be powered and work properly with the camera.

So that’s the hardware, now we discuss the software. Hands down Mark Pederson has created some fantastic hardware that in my eyes has fixed a big deficiency of the RED Epic. I no longer have to wiggle my fingers to try to install or remove those godforsaken mini Lemo cables. That’s great, good job. But more importantly it’s the peanut butter to FoolControl’s jelly. And what FoolControl, and Mikael Lubtchansky, have accomplished is such an added value to any AC or DP’s capability on set that it becomes staggering. FoolControl isn’t a solution for when your camera is on a tripod, it’s not going to bring you a lot of value when you can easily put your hands on the camera. What is does do is liberate you from needing to physically access the camera in situations where the very act of getting to the camera is difficult. This could be technocrane work, steadicam, gimbal, russian arm/vehicle work, remote cameras, even underwater housings. What FC does is give you the ability, in real time, to start/stop the camera, adjust settings in real time, playback clips, format mags, adjust color spaces and curves, etc etc etc. If you can access a feature via the touchscreen, you can do it on your laptop or iPhone/iPad.

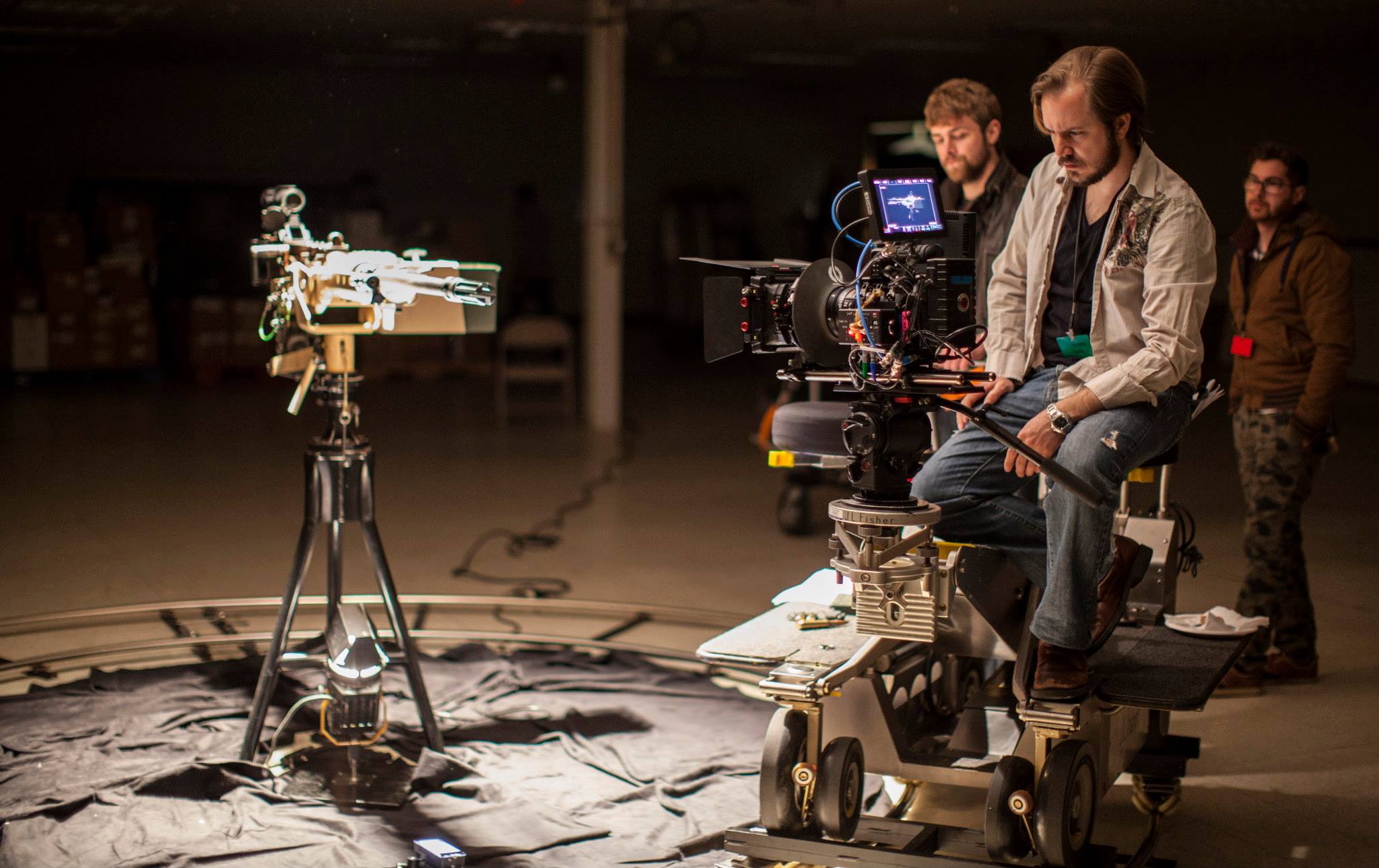

So as an example, on a shoot for Alienware this past december, we had a Dragon camera, connected via FoolControl, with a 3-channel FIZ, hanging up in the air about 30’ off the ground. The camera was locked off for a visual effects shot, and the only other way up to the camera would be via a long ladder. I hate heights, so huge pass card on that option. The most critical aspect of that situation was to be able to playback previous takes for comparisons for visual effects passes. As such being able to open the iPad, select a clip, and scrub it with more realtime response than even using a RED Touch display, was fairly exciting for the directors, client, and DP. The integration between these systems doesn’t feel like an add on, or a layer on top of the camera’s UI, it feels like a 1:1 extension. Because it offers you direct access to camera settings, it means for gimbal work you could pull off an sort of RED specific camera inputs to save weight. No more RED Touch, no more LCD cable, no more Switchblade or Sidehandle. Besides power, your RED Mag, a wireless transmitter, and a follow focus, you’d be good to go, just bolt a HotLink somewhere and go. When ounces equal pounds, you’ll take any advantage you can get.

In addition to iOS controls you have the option of using FoolControl on a laptop or desktop connected via hardline or wireless (such as using a GIG-E to ethernet control). Situations where this has been done have been live event crane work, where multiple cameras can be controlled from a central location, next to a broadcast switcher. Really, if you can imagine a situation where the capability becomes useful…it probably is useful. I’d argue that the best part of FoolControl is the elegant, and rather eye-catching user interface, which is a nice upgrade from some of the rather linear (and dig down) user interface layouts of the camera itself.

FoolControl is also in its infancy, and just in the last few months has learned a lot of new tricks, such as mag formating, blackshading, fan controls, etc. And it’s on track to mature even further. The software isn’t cheap, at nearly 200 dollars for the iOS version (allowing control of multiple cameras), and double that for the OS X version (for control of multiple cameras). This is professional software geared towards specific functions, and if you see it’s value you’ll realize these prices are bargains. FoolControl has paid for itself a dozen times over, and will continue to pay for itself.

But FoolControl is nothing without an elegant hardware implementation. I don’t see the RED Link module has a viable solution, as that module is a literal dead-end, thus creating battery plate nightmares. What Mark and Mikael have done is worked in cahoots to create a solution that relies on two amazing hardware solutions, and integrates an amazing software capability, to give tangible, and easy to use, capabilities that make the AC or DP’s life easier on set. You want playback of that clip from 5 takes ago? Hold on let me open up my iPad…and there, playing back. From a rigging standpoint the HotBox allows me to integrate systems that otherwise needed work arounds, such as PCS 1 or 3-Channel Follow Focuses, or the ability to use simple and easy to use Lemo connectors. FoolControl achieves added capabilities through elegance, strongly tied in with a hardware implementation that’s low profile (HotLink). The HotBox brings all these same capabilities as well, while reducing kluge, and providing well laid out and reliable power distribution. Which device and solution is right for you depends on your working environment, however either solution is fantastic, and well worth seeing a demo of, if not placing an order for. I commend Mark and Mikael for diving in headfirst on two bootstrap products. Both of which were ambitious solutions that had to contend with a lot of variable compatibilities. It’s still a set of products being refined, but the results are more than usable, I’d argue they’re damn near invaluable.

Suggestions- If there's anything to complain about, or rather strongly suggest for improvement it would be the following:

FoolControl needs an iPad native resolution interface, to take advantage of the 8x11 interface. Spread some of the controls around and avoid using the 2x App emulation function. It's a gorgeous UI design, take advantage of the screen Realestate.

The Hotbox needs the ability to share power with the brain via some intermediary device, so that both Brain and Hotbox (and thus accessories) can be powered off an external source such as a brick battery (VCLX). Hopefully this product is coming, because right now for studio shoots the ALEXA still has a leg up in simplicity.